|

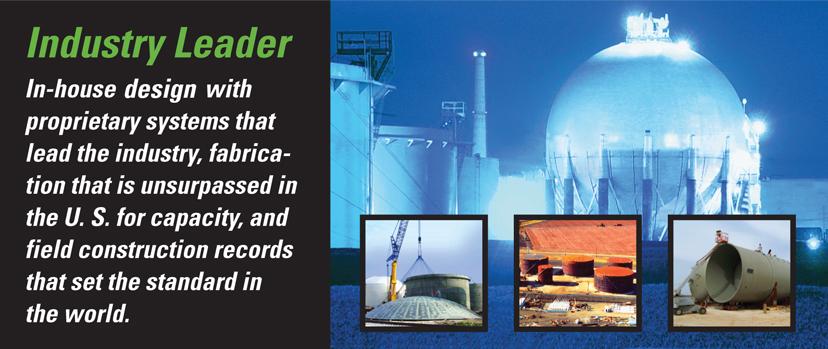

American Tank & Vessel, Inc. (AT&V) designs, shop fabricates and field erects tanks, vessels and hydrocarbon terminals. In its 30-year history, the company has grown to an international level with a consortium of partners helping deliver a complete product line to any location you desire.

Serving a broad range of industries, AT&V offers full-service tank construction and quality work above industry standards with superior schedules. In-house capabilities and waterfront facilities support manufacturing and repair projects. From planning and design to manufacturing and construction, AT&V has the technology and know-how to improve client projects.

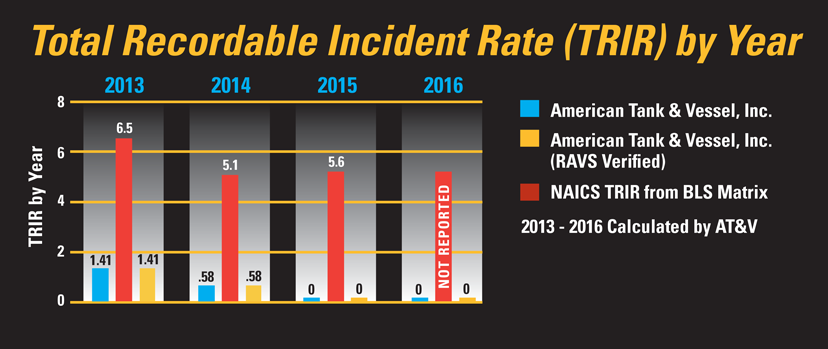

Safety is our highest priority. We strive to maintain our excellent record, realizing that our employees and the employees of our clients are the true wealth of our industry.

|

|

|

AT&V serves the world by providing industry-leading safety, quality and scheduling.

AT&V serves the world by providing industry-leading safety, quality and scheduling.